As a key technology in the modern technological field, radar is widely used in critical scenarios such as national defense security, weather monitoring, aerospace, and maritime navigation. It serves as core equipment for long-range detection, positioning, and communication. However, radar often faces challenges in extreme temperature environments. To ensure its continuous and stable operation under complex climatic conditions, high and low temperature testing has become an indispensable critical step in the research, production, and quality inspection processes.

What Is High and Low Temperature Testing?

High and low temperature testing, including high-temperature tests and low-temperature tests, aims to evaluate the operational performance of equipment under extreme temperature conditions. Its primary purpose is to examine a product’s adaptability to temperature changes during storage, transportation, and actual use.

When conducting high and low temperature tests, the following parameters require special attention:

- Temperature Set Points: Specific values set for high and low temperatures;

- Temperature Change Rate: The speed at which temperature increases or decreases;

- Dwell Time: Duration at each temperature point;

- Inspection Criteria: Clear product performance evaluation standards.

Typically, the testing sequence starts with high temperature followed by low temperature to comprehensively evaluate equipment performance.

The Core Significance of High and Low Temperature Testing

The operational stability of radar highly depends on the synergistic functioning of electronic components, mechanical structures, and signal processing systems, with temperature being a key factor affecting this synergy.

Core components of radar, such as transmitters, receivers, antennas, and signal processors, are typically made of semiconductor devices, precision circuits, and composite materials. Drastic temperature fluctuations may cause parameter drift in electronic components, structural stress due to thermal expansion and contraction of materials, and even irreversible damage such as solder joint detachment and insulation aging. Through high and low temperature testing, it is possible to verify in advance whether the radar can power on normally, detect targets, and transmit signals under extreme temperature conditions, thereby avoiding functional failures in practical applications.

Testing Methods and Procedures

- Testing Purpose: To examine the applicability of Lakeda products in high and low temperature environments;

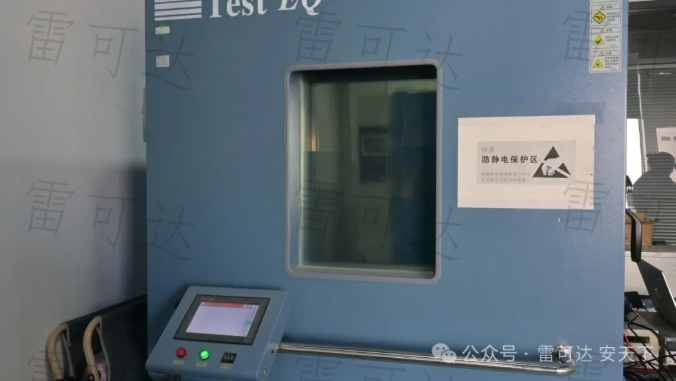

- Testing Equipment: High and low temperature test chamber;

- Test Samples: Lakeda products;

- Testing Content: Unpackaged products in a powered-on state are placed in the test chamber in their normal orientation. The high temperature is set to +55°C, and the low temperature to -40°C. After temperature stabilization, the test continues for 48 hours, followed by inspections of appearance, structure, and functionality;

- Evaluation Criteria: Passing basic functional tests with normal appearance, structure, and functionality.

Core Aspects of High and Low Temperature Testing

Combining general testing methods with radar structural characteristics, high and low temperature testing primarily includes the following aspects:

1. Core Performance Parameter Testing

- Transmission and Reception Performance: Monitor radar transmission power, operating frequency band, and reception sensitivity in high-temperature (+55°C) and low-temperature (-40°C) environments to ensure detection range and resolution meet design requirements;

- Signal Processing Accuracy: Test the impact of extreme temperatures on signal filtering and target recognition algorithms, evaluate errors in range, velocity, and angle measurements to prevent target misjudgment or missed detection.

2. Structural and Mechanical Stability Testing

- Moving Parts: Examine the rotational accuracy and response speed of the servo system in rotatable scanning radar under high and low temperature environments to avoid jamming or abnormal noises caused by lubricant solidification (low temperature) or component expansion (high temperature).

3. Long-Duration Operational Reliability Testing

- Continuous Monitoring Method: Place the radar in extreme temperatures for continuous operation over 48 hours, record its operational status, including occurrences of automatic shutdown, data interruption, or false triggering of overheating protection, to evaluate its sustained operational capability under extreme conditions.

4. Temperature Cycle Shock Testing

- Simulating Drastic Temperature Difference Scenarios: Test the thermal shock resistance of various radar components, check for cracked circuit solder joints, loose connectors, and degraded insulation performance to ensure structural stability under rapid temperature changes.

5. Auxiliary System Adaptability Testing

- Power Module: Examine the stability of output voltage and overload protection functionality of the power supply under high and low temperature conditions to prevent power supply abnormalities;

- Heat Dissipation System: Verify the efficiency of cooling fans and heat sinks in high-temperature environments to ensure the temperature of core components does not exceed critical limits.

Note: The above data is derived from internal product testing at Lakeda.

Conclusion

Radar is hailed as the “nerve endings for perceiving the external world,” and its stability is directly related to national security, public safety, and production efficiency. Through systematic high and low temperature testing, not only can Lakeda products be ensured to operate stably in extreme environments such as polar regions, deserts, and high altitudes, but it also drives continuous optimization in weather resistance, lifespan, and reliability. In the future, with ongoing advancements in testing technology, high and low temperature testing for radar will become more efficient and precise, providing robust guarantees for applications in various complex scenarios.

Related Readings

- National Standard for Environmental Adaptability Testing (GB/T 2423) — Official standard inquiry platform of the National Standardization Management Committee, providing public access and download services for national standards

- Radar Systems and Technology Special Topic — IEEE Xplore Digital Library, featuring cutting-edge papers and industry standards in radar technology and environmental testing

- Defense Equipment Environmental Testing Method Guidelines — Weapons and Equipment Demonstration Center Standard Specification Service Platform, publishing test specifications and implementation requirements for military, aerospace, and other fields

(Note: The official website of the Ministry of Industry and Information Technology requires accessing specific content through the “Government Affairs Openness - Standards and Specifications” section. Here, it is replaced with more targeted authoritative platforms.)